Our productivity has gone up by applying Tanaka tec’s Gantt chart method!- PREX Island

Ex-participants KAIZEN platform

Our productivity has gone up by applying Tanaka tec’s Gantt chart method!

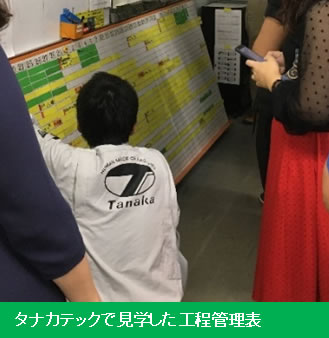

I am AKIM Gulmaira from a company called Asylmura. Our business includes production and sales of bags with Mongolian Kazakh embroidery. I visited Tanaka tec Co., Ltd. for the training course in Japan in 2018 and heard about their 3S activities. Having seen their Gantt chart in the visit, I thought that it could be applied in our company. No sooner had I come back to my country than I started using it in my company. As it is made with a magnet, it is handy and easy to put up or take off.

The reasons why I applied the Gantt chart is to make it “visible” and to implement Ho-Ren-So (to report, inform and consult). It is time-consuming to write down on paper and manage it; however, anyone can supervise it, and it is easy to amend in the case of error, as it is made with a magnet. Until then, we used to use paper documents for inventory control and often failed to record it, but now, we can just write “100” in goods column of the chart, if we take 100 of certain goods, so issues related to omissions have been solved. The chart is also effective to prevent stock shortage of materials. From the point of view of the managing director, I sometimes need information from the production system promptly. In that case, I can grasp the situation whenever I want by receiving photos of the chart.

It has been two months since the chart was put up. In my company, our employees do work from home such as making embroidery, and their work is interrupted if cloths which are allocated to them run out. Making our work “visible” by managing employees’ work progress with the chart enables us to allocate adequate amount of cloths to each employee. It resulted in doubling or tripling the productivity. I was thinking of hiring more workers, but there is no need to do so any more.

The biggest benefit of the chart is that the employees have become aware of production volume. At present, giving the employees the chart with the amount of cloths, they can work, aiming for their targets. We also try to make the chart easy to understand by putting photos of products.

We tried to improve the chart a few times since we started using it. Although it is not sufficient yet, we will aim to carry on kaizen!

(Content of the photo)

Products which craftsmen and crafts women decorated

The Gantt chart used in Glumaira’s company

The Gantt chart seen at Tanaka tec

Professor Minagawa’s Comment

It is brilliant that she has been implementing what she had learnt at Tanaka tec, and it has been producing good results. I hope that she will upgrade the level of 3S and 5S in Mongolia by sharing not only within her company but also with other companies. The reason why we lecture at the training courses is to not contribute to just the profit of one company because if we contribute to only one company, we need to ask for consultation fees from the company. Please share what you learnt with other companies.

- Date : February 21, 2019

- Name : Ms. AKIM Gulmaira(Mongolia)

- Seminar : Participant of JICA Mongolia Capacity Development of Business Persons in 2018

- job name : General Director