Kyrgyz: Things participants learned at Japanese companies- PREX Island

Ex-participants

Kyrgyz: Things participants learned at Japanese companies

|

Kyrgyz Elgiza Bekenova, President of a maternity wear company |

I visited a variety of Japanese companies in March 2015 while taking a seminar in Japan. Here, I will report on the things I learned at Japanese companies.

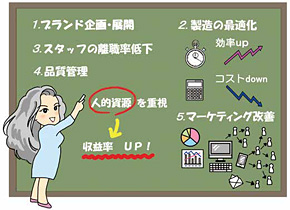

The first point is brand planning and development, which I learned about from Ooue, a traditional business of “washi” paper. Ooue developed new products at a time when it faced management difficulties, and the moves sustained the company and gave it a high level of growth. When I actually visited and saw the washi products, I thought I needed to develop new products, even in Kyrgyz, and to expand my line.

The second point is the optimization of manufacturing. The manufacturing factories I saw on field trips in Japan were carrying out extremely efficient production. They had also incorporated Kaizen, and I was made aware of case studies about companies doubling their sales as a result of Kaizen. My company is conducting Kaizen bit by bit. Costs are coming down, efficiency going up and sales rising.

The third point is reducing the staff turnover rate. The manufacturing and sales of women’s clothes in Kyrgyz is a tough business. The turnover rate among staff is high, and that was a big problem for me. The situation is that an employee will move if another company is offering even slightly better conditions. I visited a variety of companies in Japan. One was Juno Beauty (a chain of beauty salons), where I found out how it trains its staff and develops its human resources. I adopted Juno Beauty’s principles and implemented them at my own company. We hold various events not related to work within the company, and not one employee has quit during the last six months.

The fourth point is quality control. From lectures at two companies – Hotel Park Hyatt Tokyo and Kansai Home Service — I was able to find out the extent of service-quality improvements said to be necessary. After getting back to my company, I explained that quality control is an issue for each and every employee. Previously, the employees dealt with their own work in silence. Now, each and every one takes on more responsibility and has started to do quality control. Motivation has also risen, and a sense of loyalty has been created. They are aiming for further improvements to the manufactured goods they make.

The fifth point is Kaizen for marketing. The market for women’s clothing is an extremely difficult one. While in Japan, I visited Mo-House, a company that makes maternity wear. This company has forged ties with society and is engaged in extremely unique activities in the Japanese market. The products aren’t merely products but reflect the company’s spirit and philosophy. The company has transmitted a message stating that it supports the idea of having an active pregnancy period. I thought Mo-House’s concept was fantastic. When I thought I wanted to do the same kind of thing at our company, we came out with huge results in terms of company achievements. This led to a rise in sales and improvements to profitability.

I visited the country of Japan, and the point about “stressing human capital” left a deep impression on me. I believe that Japan became a technological superpower by utilizing its human resources. In my area of business, I have learned a lot of things from the Japanese business model. Since my company’s experiences are of deep interest to other Kyrgyz people, I am introducing them at a university graduate school, etc.

- Date : July 30, 2016

- Name : Elgiza Bekenova san

- job name : President