Bringing ‘Kaizen’ to Ethiopia (implemented in May 2010)

Seminar in Japan: Survey to Improve Product Quality and Productivity in Ethiopia

The Japan International Cooperation Agency (JICA) is currently carrying out its Kaizen Project (a survey to improve product quality and productivity) in Ethiopia, running from 2009 to 2011. Ten public-sector officials (of the Kaizen Unit) and 10 managers and executives from the pilot enterprise* took part in the seminar in Japan. The participants learned about the situations and results of actual Kaizen practices at Japanese companies through field trips and other activities.

* A Kaizen Project model enterprise

Visits to 10 Kansai companies

The Ministry of Trade and Industry of Ethiopia established its Kaizen Unit. It embarked on human-resource development aimed at spreading Kaizen activities within Ethiopia and started a project that carried out analyses and guidance at 30 domestic companies. Participants in this study group had previously learned the basic content of Japan’s Kaizen activities while in Ethiopia from Japanese experts. For the visiting mission, a point was firmly made “to personally experience the effectiveness of Kaizen after observing Kaizen activities practiced in Japan.”

Programs were drawn up that would, as much as possible, present specific Kaizen case studies so as to encourage Kaizen activities currently being implemented in Ethiopia. We received a huge amount of assistance from all of the companies that were visited in consideration of the seminar participants, such as cut-and-dry presentations of the results of Kaizen practices, which had been accumulation of efforts taking place day after day.

A total of 10 companies kindly consented to receive the visits. The point was made of the struggle involving the original Kaizen practices, the methods by which those practices are started up, situations by which they are implemented, and issues on how they are vitalized, as well as how the practices were built up and the kind of results produced. Without a doubt, the companies allowed the participants to see “living Kaizen” at the very locations where it is performed.

A field trip to Nakagawa Sangyo Co., Ltd.Company officials explain how they implemented Kaizen and its effectiveness.

Participants from Ethiopian companies

The companies selected by the pilot project, which carried out analyses and guidance for each of the 30 domestic companies, fell into five sectors: 1) metal and machinery; 2) chemicals; 3) processing of agricultural products; 4) textiles and garments; 5) leather.

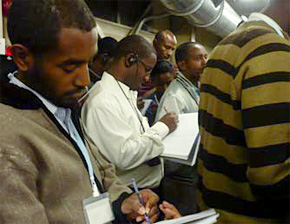

Ten of the 30 companies sent managers and executives to the seminar in Kansai. The gathering included a quality manager at an Ethiopian pulp and paper company, a quality assurance manager at a pipe company, a senior production engineer from a cotton-spinning company, the president of a metalworking company, the manager of a leather company, an R&D manager for trade and industry, a production manager of a food products company and the deputy chief of a cooking-oil factory. They studied with great passion toward the goal of introducing Kaizen practices at their own companies.

- Participants learn about Kaizen activities at a food-processing company.

- A field trip at a factory of Nishigaki Kutsushita.

Miyuki NISHIZAKA

Course Planner, International Department

Seminar summary

| Name | Survey to Improve Product Quality and Productivety in Ethiopia |

| Period | May 10 (Mon.) to 21 (Fri.), 2010 |

| Participants | 10 members of the Kaizen Unit, a counterpart organization, and 10 corporate participants |

| Commissioned by | Osaka International Center, Japan International Cooperation Agency (JICA) |